How woven mesh is used in the automotive industry

Woven mesh finds various applications in the automotive industry due to its versatility, durability, and strength. Here are some common uses:

- Airbag Deployment: Woven mesh is used as a filter material in airbag deployment systems. It ensures that the gas generated during airbag deployment is clean and free from debris, allowing for efficient and safe inflation.

- Catalytic Converters: Catalytic converters in automobiles use woven mesh as a substrate for the catalyst material. The mesh provides a large surface area for the catalyst to react with harmful emissions, such as nitrogen oxides, carbon monoxide, and hydrocarbons, converting them into less harmful substances.

- Exhaust Systems: Woven mesh is employed in exhaust systems to improve filtration and reduce noise. It helps in trapping particulate matter and minimizing emissions before they are released into the atmosphere.

- Engine Filtration: Woven mesh is used in engine air intake systems and oil filtration systems to prevent contaminants from entering the engine. It ensures the longevity and efficiency of the engine by maintaining clean air and oil circulation.

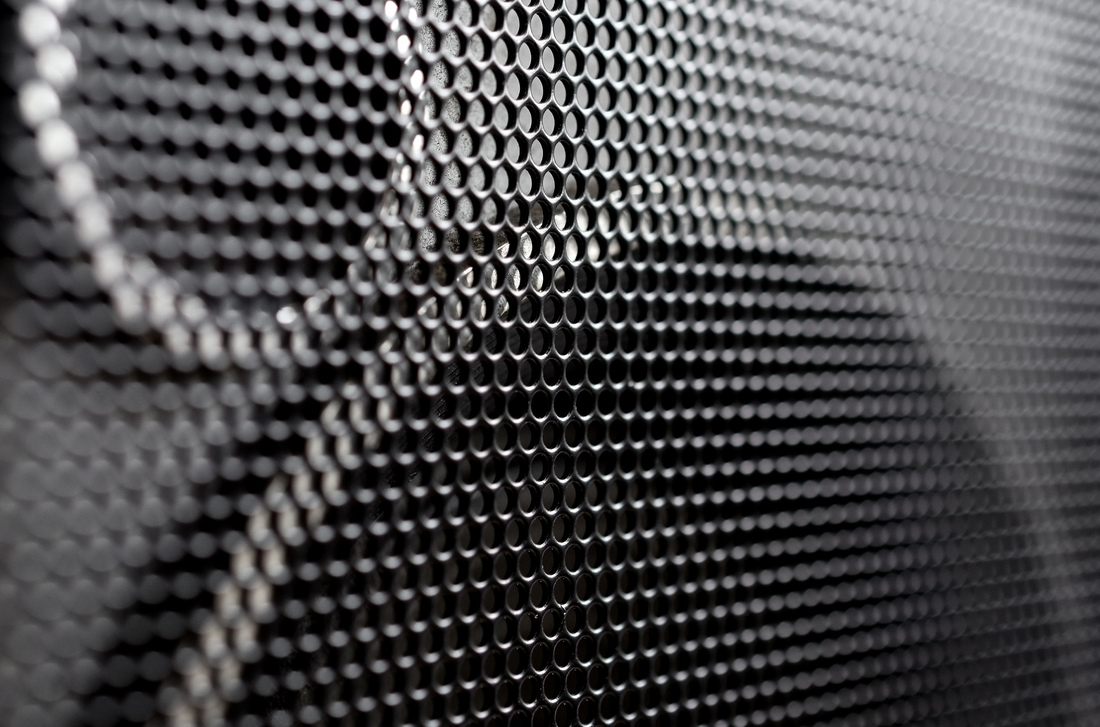

- Grilles and Mesh Screens: Woven mesh is commonly used in automotive grilles and mesh screens for aesthetic purposes as well as for protection against debris and insects. It provides a durable and visually appealing solution for front-end design.

- Seat Construction: Some automotive seats utilize woven mesh as a supportive material. It offers breathability and comfort while maintaining structural integrity, making it suitable for both traditional and sporty seat designs.

- Battery Packs: In electric vehicles (EVs) and hybrid vehicles, woven mesh can be used as a component in battery packs. It helps with thermal management by facilitating airflow and dissipating heat generated during charging and discharging processes.

- Safety Restraints: Woven mesh can be incorporated into the design of safety restraints such as seat belts and harnesses. It enhances strength and durability while ensuring proper distribution of force during sudden impacts.

Overall, woven mesh plays a crucial role in enhancing the performance, safety, and aesthetics of automotive components across various applications in the industry.

Woven mesh offers several benefits when used in the automotive industry:

- Strength and Durability: Woven mesh is typically made from strong and durable materials such as stainless steel, making it capable of withstanding harsh environmental conditions, vibrations, and impacts commonly encountered in automotive applications. This enhances the longevity and reliability of automotive components.

- Customization: Woven mesh can be tailored to meet specific design requirements, including size, shape, and mesh density. This flexibility allows for customization to fit various automotive applications, ensuring optimal performance and functionality.

- Filtration Efficiency: Woven mesh serves as an effective filtration medium, capable of trapping particles and contaminants in air, oil, and exhaust systems. By maintaining clean air and fluid circulation, woven mesh helps to protect vital automotive components, improve engine performance, and reduce emissions.

- Thermal Management: In applications such as battery packs and exhaust systems, woven mesh aids in thermal management by promoting airflow and dissipating heat. This helps to prevent overheating, optimize operating temperatures, and enhance the efficiency and lifespan of automotive systems.

- Lightweight: Despite its strength and durability, woven mesh is relatively lightweight compared to solid materials, making it suitable for applications where weight reduction is desirable, such as in fuel efficiency and vehicle performance improvements.

- Aesthetic Appeal: Woven mesh can be aesthetically pleasing, adding a stylish and modern touch to automotive components such as grilles, trim panels, and interior accents. Its versatility in design and finish options allows for the creation of visually appealing automotive designs.

- Noise Reduction: Woven mesh can act as a sound-dampening material when used in exhaust systems and other components. By reducing noise levels, it contributes to a quieter and more comfortable driving experience for passengers.

- Safety Enhancement: In safety-related applications such as airbag deployment systems and seat construction, woven mesh helps to enhance safety by ensuring proper airbag inflation, providing structural support, and distributing forces evenly during impacts.

Overall, the benefits of woven mesh in the automotive industry encompass improved performance, durability, efficiency, safety, and aesthetics, making it a versatile and valuable material for various automotive applications.