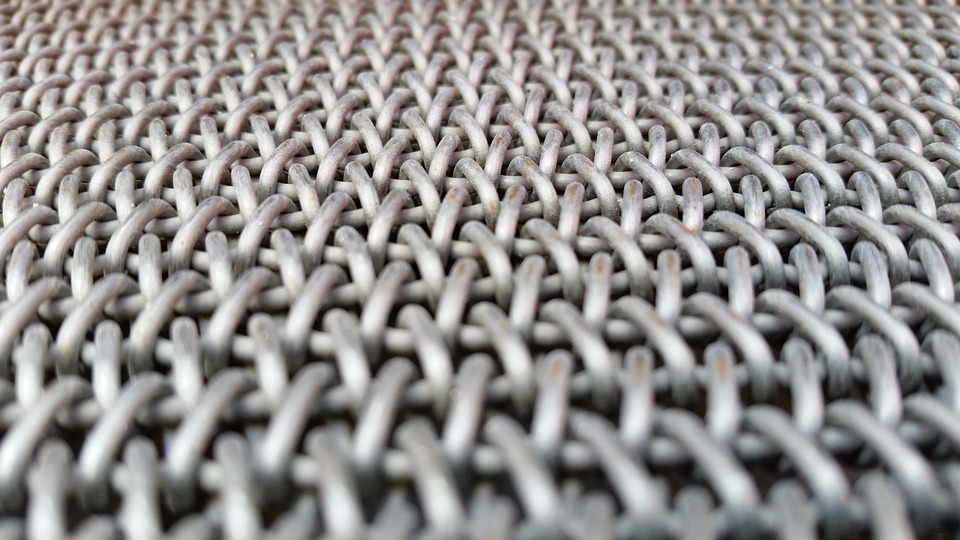

The Annealing Process

It’s a process often used after weaving wirecloth. It allows the mesh to be more easily shaped or pressed into complex forms. It can also be useful to soften wires after they’ve been cold-drawn, which reduces their diameter. The softened wires can then be more easily weaved.

Types of Annealing:

1) Full Annealing

This involves heating steel to 30-50°C above its critical temperature of 723°C before allowing it to naturally cool down inside the furnace.

2) Process Annealing

This is a cheaper method; the metal is not heated to as high a temperature or cooled in the furnace. It is used to treat work-hardened parts made out of low-carbon steels.

Cold worked steel usually possesses increased hardness and less ductility (ability to deform under tensile stress or be stretched into a wire), which makes it harder to work with. Process annealing improves these characteristics and is mainly carried out on cold rolled steel.

3) Stress Relief Annealing

Large castings and welded structures are prone to internal stresses causes mainly during their manufacture and uneven cooling. This can cause isolated brittleness, which can lead to breaks in the metal.

Stress relief annealing is suited to this type of metal. It is heated to about 650°C and then maintained at this temperature for a few hours before being allowed to slowly cool.

4) Spherodise Annealing

This method is suited to high carbon and alloy steel, improving the internal structure for improved machinability. It can be carried out by either heating the metal to about 700°C and maintaining it at this temperature for eight hours or by heating and cooling the metal intermittingly just above and below the lower critical temperature.

5) Isothermal Annealing

This involves heating the metal to above the upper critical temperature of steel before force-cooling it to its lower critical temperature and maintaining it at this temperature for a set amount of time. This process is mainly used on low carbon and alloy steels.

Interested in woven metal mesh? Read our other articles here.