Insect Screening

Our range of flyscreen is used throughout the world and is used in many different ways in order to control the passage of all forms of insect and reptile life - as well as enabling companies and individuals to comply with increasingly stringent controls on health and safety, food hygiene and environmental regulations.

We offer here a selection of the most popular materials together with their technical specifications.

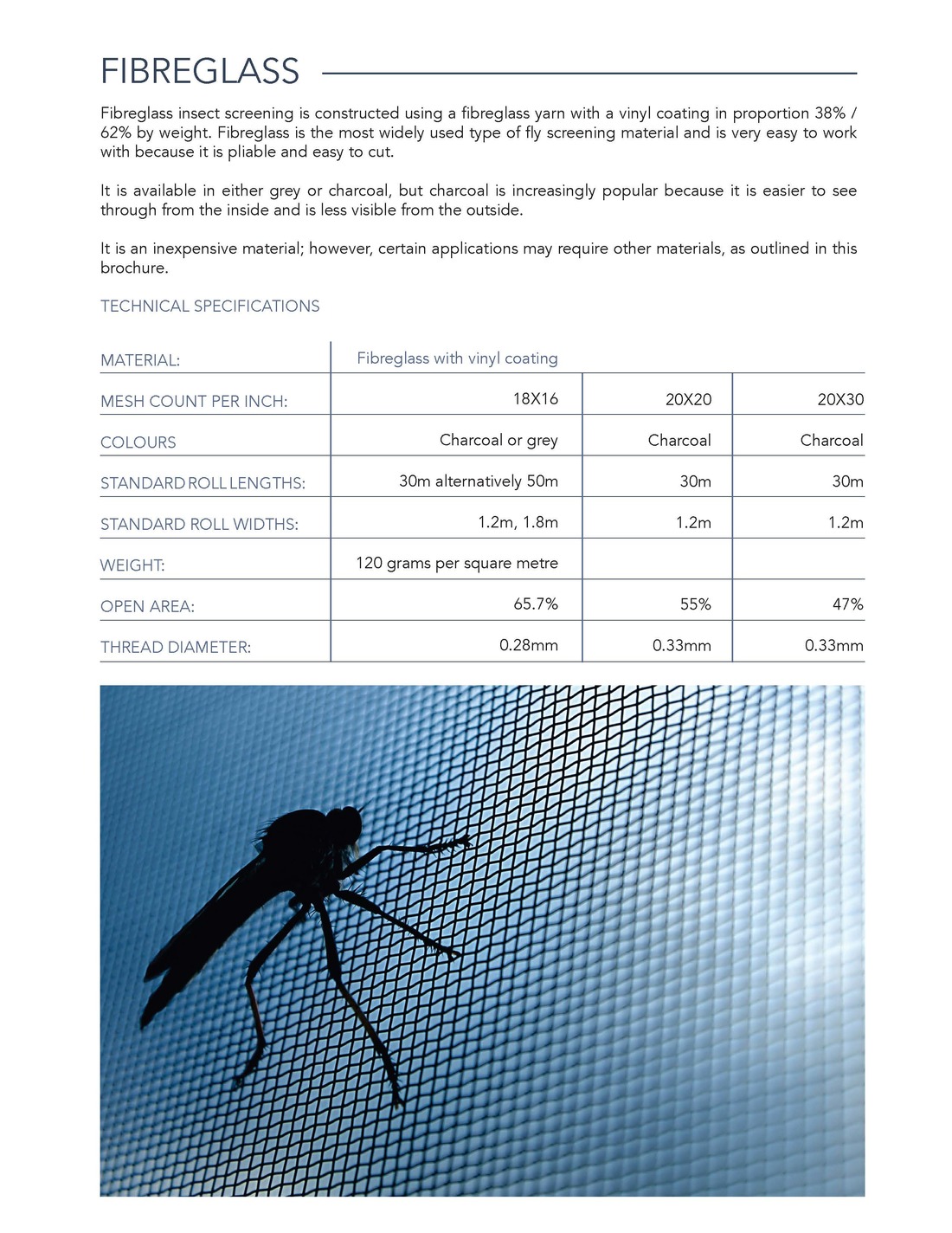

Fibreglass

Fibreglass insect screening is constructed using a fibreglass yarn with a vinyl coating in proportion 38% / 62% by weight. Fibreglass is the most widely used type of flyscreening material and is very easy to work with because it is pliable and easy to cut.

It is available in either grey or charcoal, but charcoal is increasingly popular because it is easier to see through from the inside and is less visible from the outside.

It is an inexpensive material however certain applications may require other materials, as outlined in this brochure.

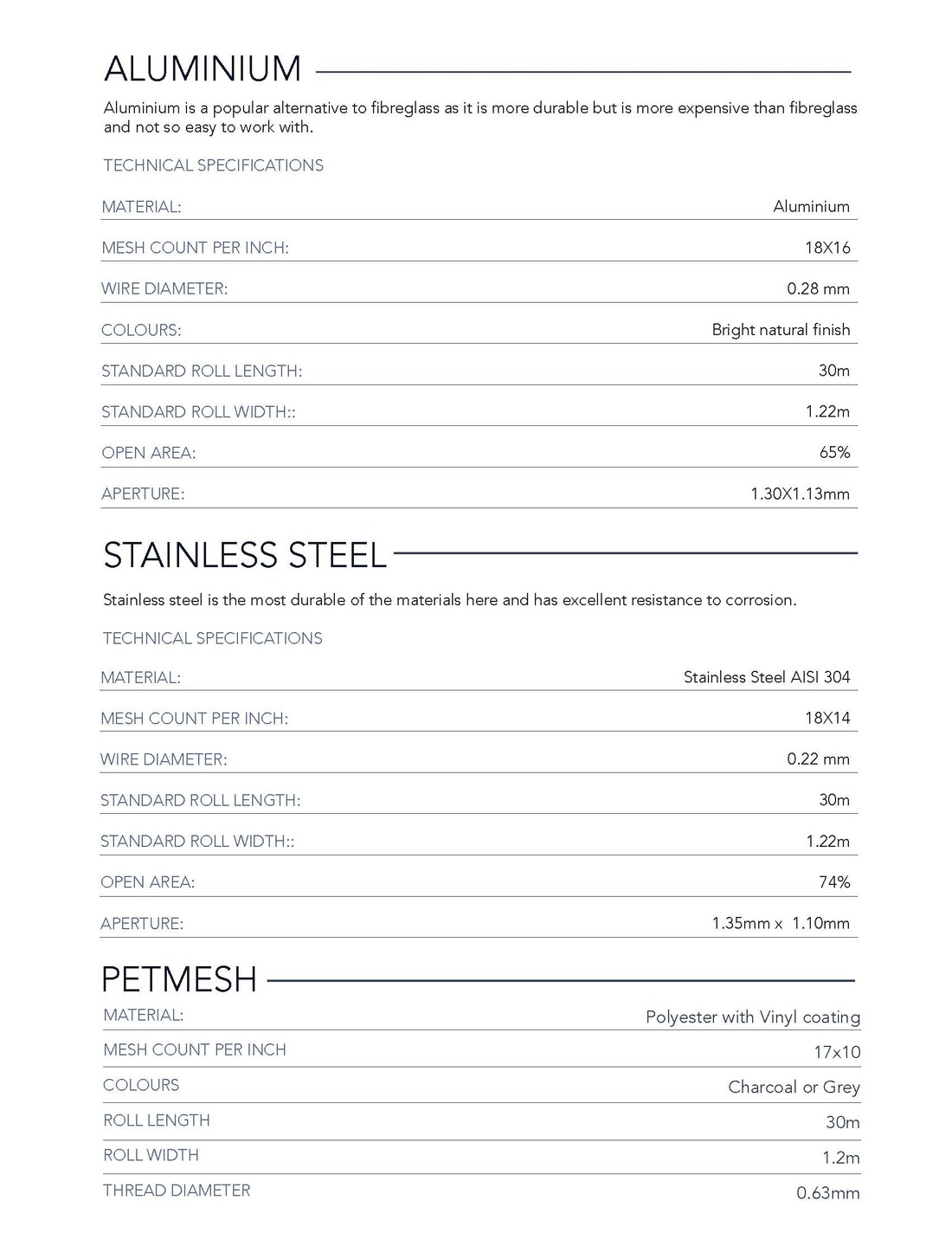

Aluminium

Aluminium is a popular alternative to fibreglass as it is more durable but is more expensive than fibreglass and not so easy to work with.

Stainless Steel

Stainless steel is the most durable of the materials here and has excellent resistance to corrosion. It is the most expensive of the four material offered.

Product Tables: