Welded Wire Mesh

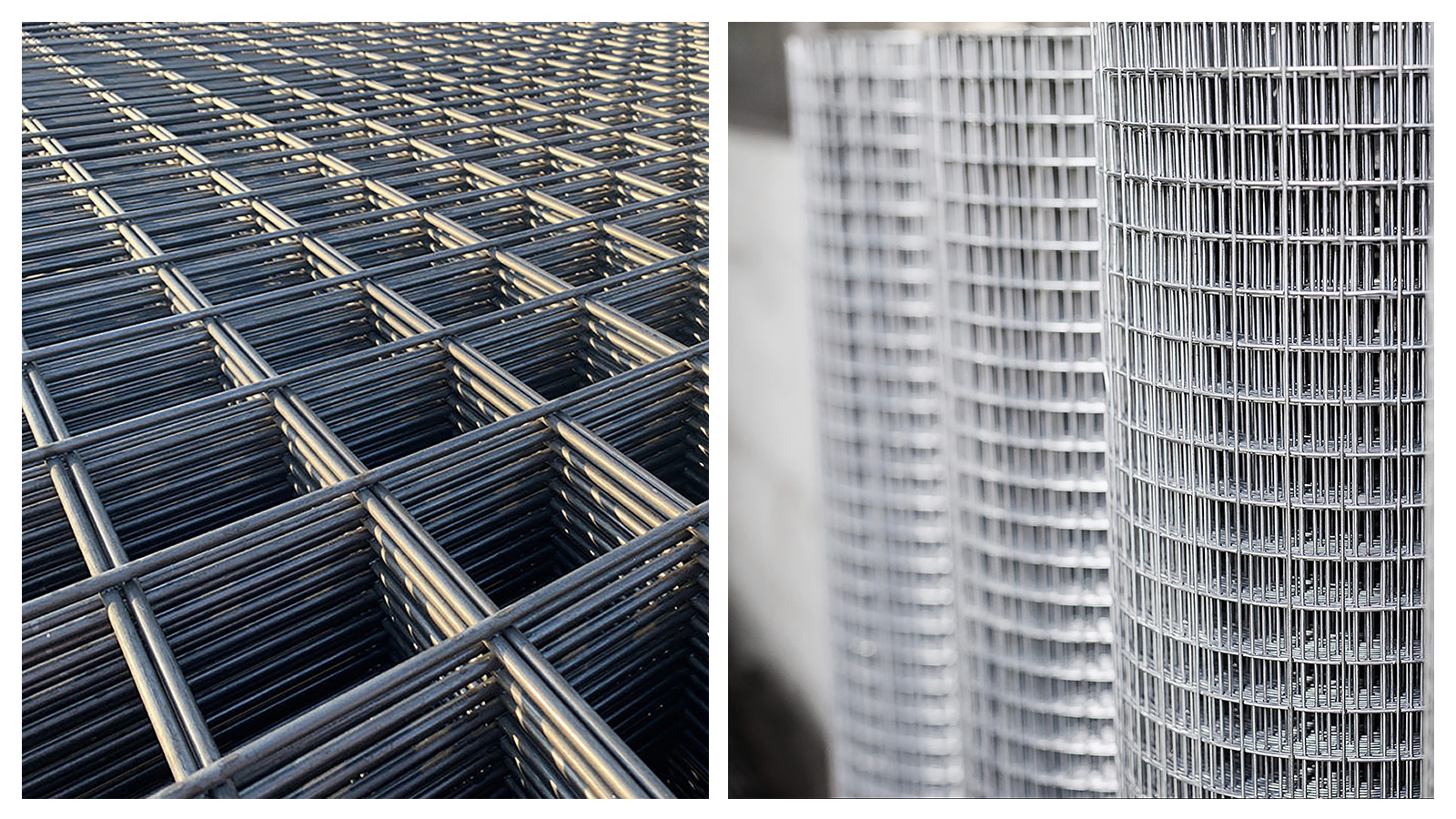

Welded Wire Mesh has wide applications in the construction, agricultural and engineering industries due to its high rigidity and strength. It is increasingly used in security applications and as machine guards.

The popular sizes are available from stock in standard sheets and rolls. We hold the largest ex-stock range in the UK.

We can offer a cut to size panel service and supply non-standard mesh size to order.

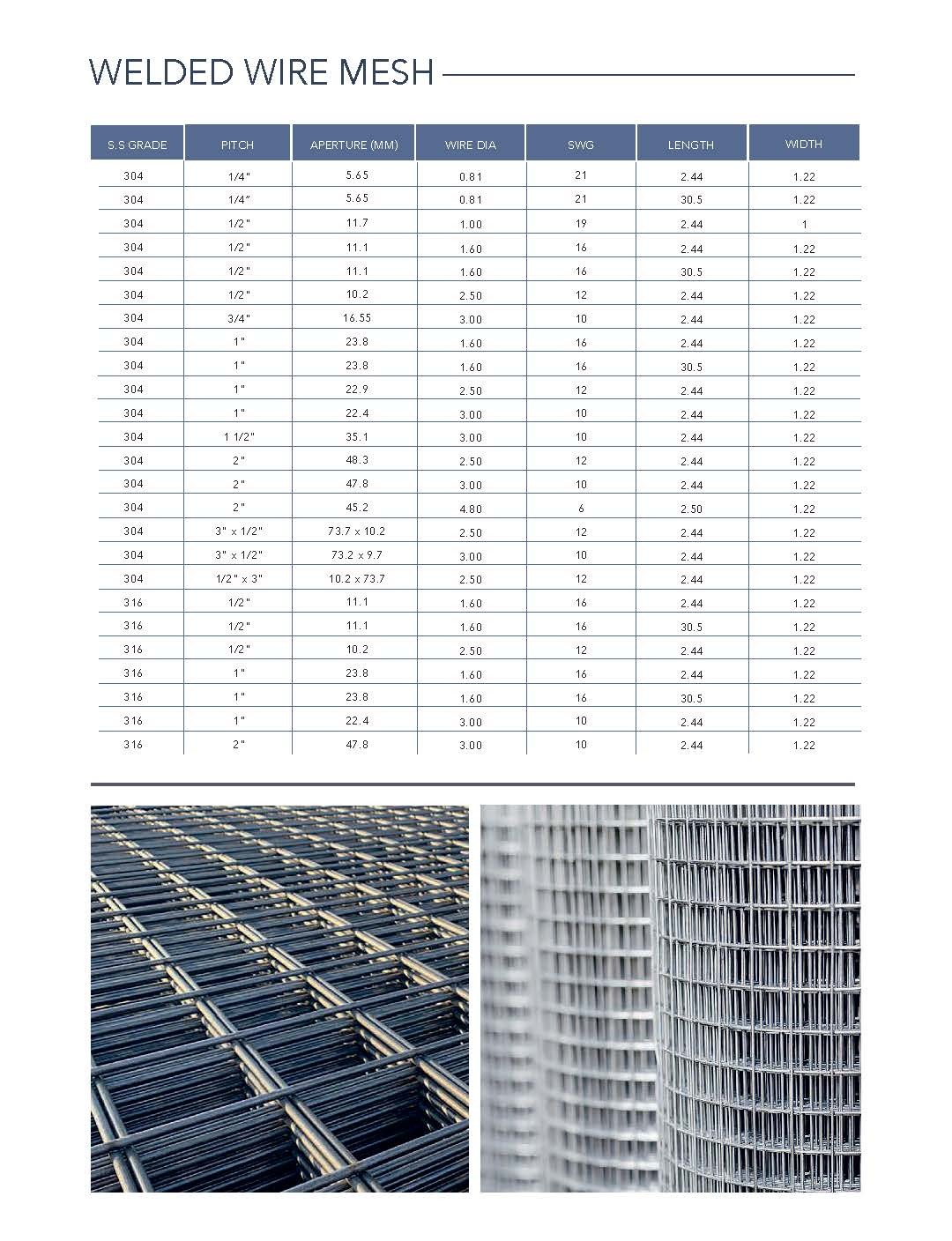

Product Tables: