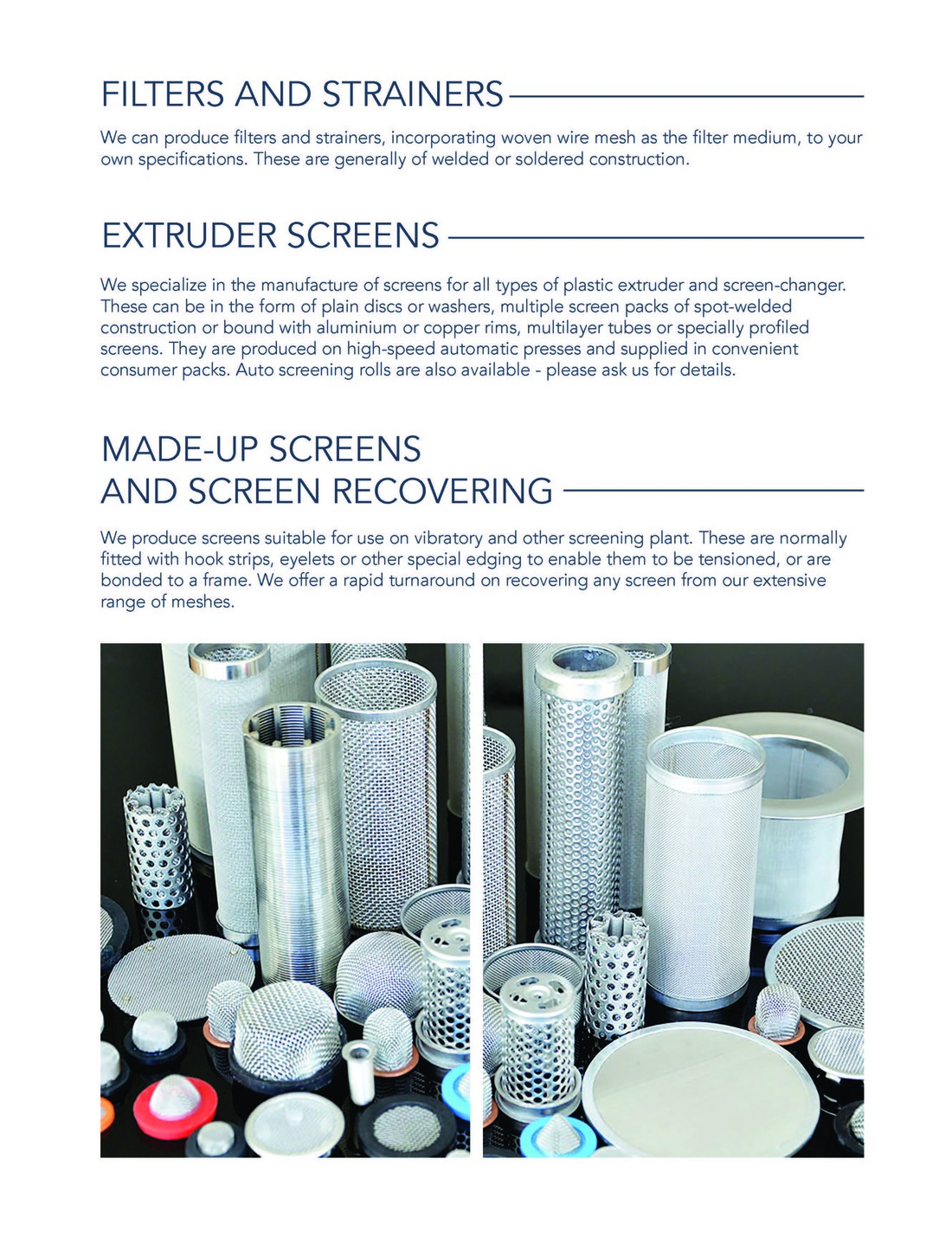

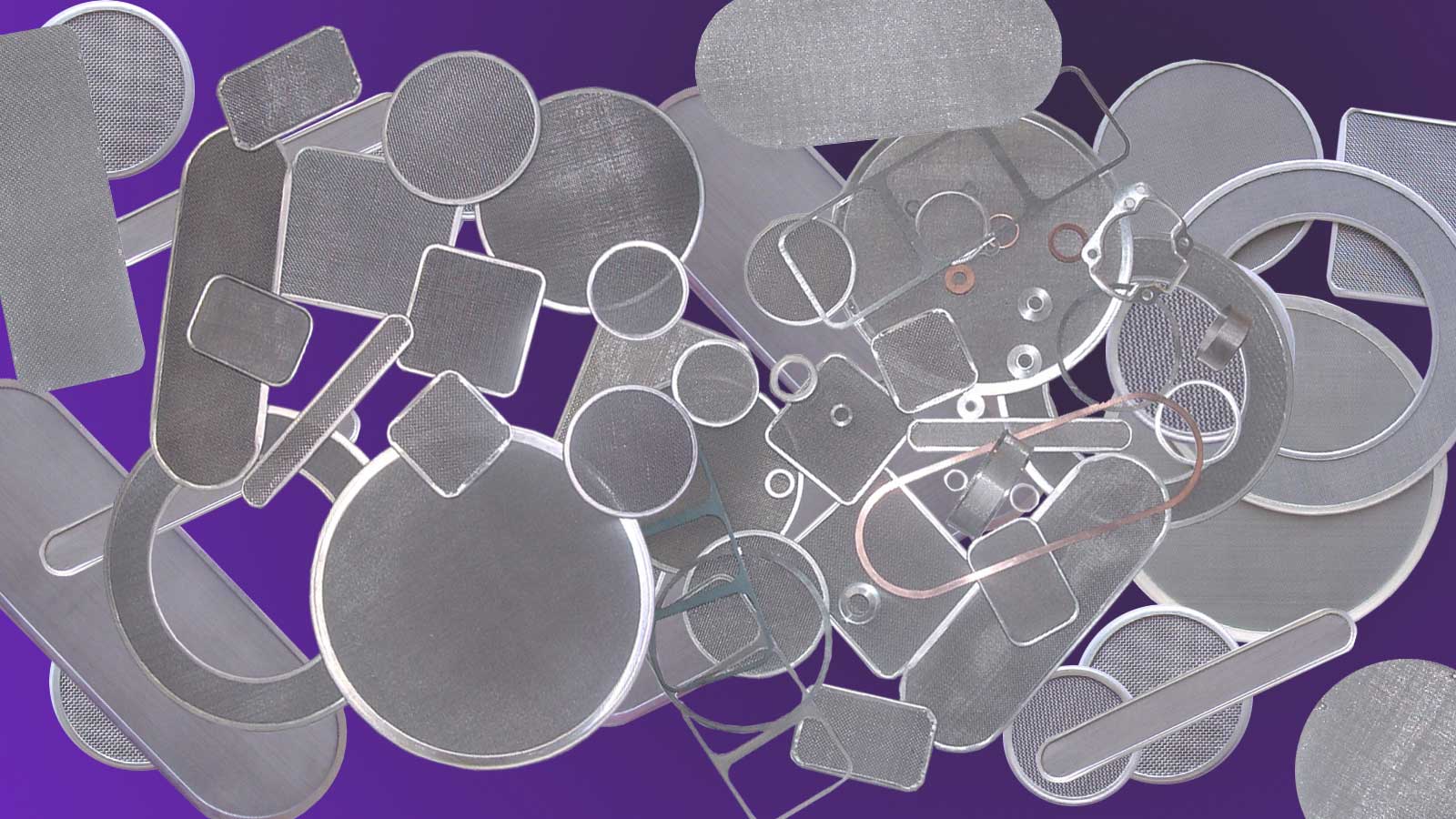

Filters and Strainers

Extruder Screens

We can produce filters and strainers, incorporating woven wire mesh as the filter medium, to your own specifications. These are generally of welded or soldered construction.

We specialise in manufacturing screens and with more than 135 years of practice, we are able to offer a variety of extruder and screen changer options.

Our screens can be in the form of:

- Plain discs or washers

- Multiple screen packs of spot-welded construction

- Bound with aluminium or copper rims

- Multilayer tubes or specially profiled screens

- Autoscreening rolls

Our extruder screens are produced on high-speed automatic presses and they are all supplied in a neat and convenient pack for you.

Made-up Screens and Screen Recovering

We produce screens suitable for all types of screening plant, even vibratory.

These types of screens are usually fitted with hookstrips, eyelets or other special edging to enable them to be tensioned or bonded to a frame and to make life even easier, we’ll also recover any screen from our extensive range of meshes, quickly and efficiently.

Product Tables: